Asking a thermal energy network enthusiast “Do you want to go to Framingham?” is like asking “Do you want to go to Disney World?”

Framingham, Massachusetts, is home to the nation’s first operational utility geothermal network (GEN). Non-utility GENs already heat and cool buildings across the country. But Eversource Energy’s June 2024 launch was the first time a utility converted a neighborhood from gas to geothermal—making it a big deal for neighborhood-scale building decarbonization. A big enough deal that more than 30 thermal energy fans trooped out to Framingham on a 34°F (1°C) morning in February to see the network.

Except: See what? A geothermal network is mostly invisible. Its structure is underground, where pipes loop through boreholes, then connect to dispersed geothermal heat pumps, moving thermal energy to and from buildings. Aboveground, it looks like any other neighborhood.

But as we saw on our tour, there are clues to the groundbreaking work below.

On a February morning, we gather in the Framingham Public Schools parking lot to meet members of teams behind the project: Eversource Energy, Celsius Energy, and nonprofit HEET.

Above, BDC’s Ashley Besic examines Celsius Energy’s diorama of the Framingham GEN. The top is a neighborhood map. See the delicate sticks that fan out below the neighborhood? Those are the boreholes that burrow into the ground for thermal energy right beneath Ashley’s feet.

If you were to lift this manhole cover and crawl beneath it (which, for the record, you shouldn’t), you’d find yourself in a space about the size of a phone booth where 17 boreholes converge. Instead of drilling vertically, this project deployed a pyramidal drilling technique. Boreholes join at a single point, then slant outward.

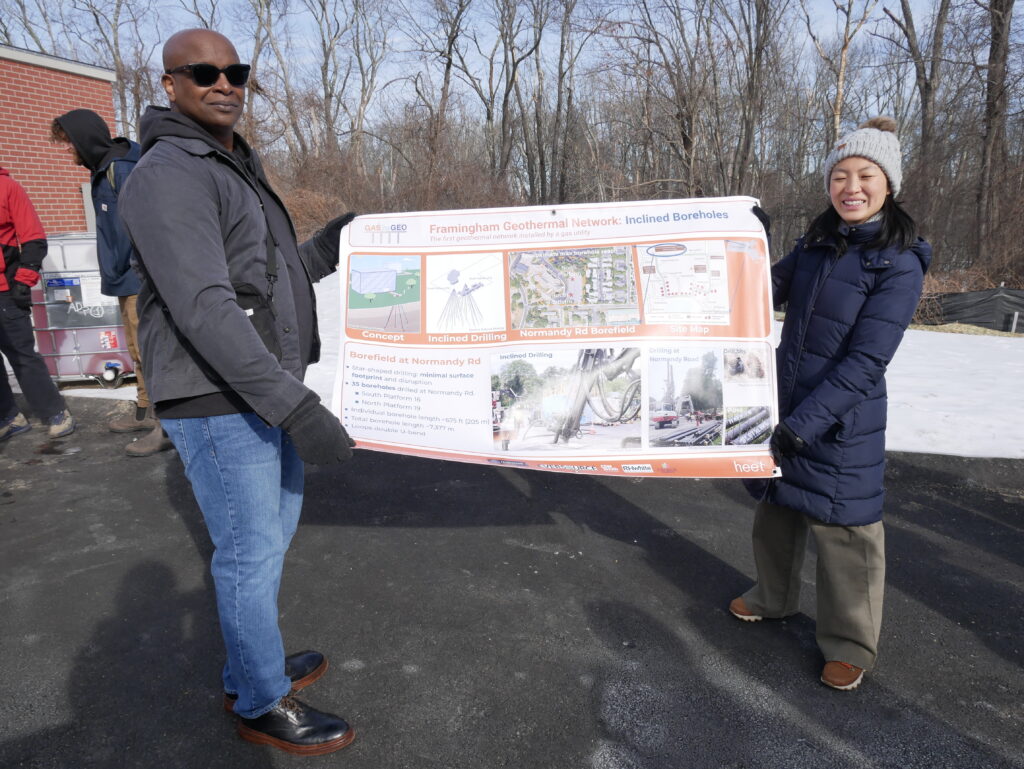

Tony Berry (HEET) and Yaning Zhang (Celsius Energy) explain how this pyramidal drilling technique shrank the construction footprint. Celsius Energy is a geothermal design-build firm that innovates geothermal solutions. Their design and engineering team was able to reduce the project’s footprint from 60 vertical boreholes with 60 different origin points to just 35 inclined bores on the largest lot. That resulted in a 90% reduction in surface footprint and a 74% reduction in surface piping material.

This made several community members happy: the parking lot remained usable for school teachers and staff during construction, and the borefield’s nearest neighbors—turtles and other wetland wildlife—faced minimal disruption.

Eric Juma (HEET, right) and the BDC’s Ania Camargo Cortés showcase the project’s data collection. Partnering with a team that included UC Berkeley’s Soga Research Group—plus Eversource, RH White, Celsius Energy, and MidWest Geo—HEET kitted out 15 boreholes with distributed fiber optic sensors.

Eric explains it best: “Each fiber optic cable terminates at the data collection device near the pumps and runs alongside the horizontal piping to its respective borehole. From there, the cable continues down the full length of the borehole. By sending pulses of light down the fiber and analyzing the responses, we can measure temperature at every point along the fiber, creating a detailed thermal map of the subsurface—both across the borefield and along its depth.”

We step inside the pump house, where Ashley and Paul Bony (Yampa Valley Sustainability Council) are thrilled to see: pipes!

These pipes are the veins of the geothermal network. Flowing through them is water and propylene glycol (an antifreeze that, incidentally, is also commonly used as a food and cosmetics additive). The water-based mixture circulates through the loop like a mailman delivering mail to and from houses, except it’s delivering thermal energy to and from heat pumps.

On the day of our visit, the temperature of the water was 47°F (8°C) when it left the borefield beneath the parking lot and entered the pump house. After circulating through the loop, delivering and collecting thermal energy from all buildings, the water returned to the pump house at 44°F (7°C). This small Delta T (ΔT), or change in temperature, indicated the network was well-balanced. Water wasn’t returning cold and depleted, nor was it returning overheated.

Eric Bosworth (Eversource) shows Paul the GEN’s backup electric boiler. In the unlikely event that the temperature in the pipes drops below 32°F (0°C), the boiler can heat water to send thermal energy to homes. This boiler was an extra resilience measure. Ideally, it will stay off, Eric explains, “but it’s an option if we need it.”

Electric appliances, including the geothermal heat pumps used by GENs, draw power from the electric grid. As neighborhoods transition to electric heating and cooling, we must ensure our grid can meet the growing demand for electricity. In Framingham, however, projections show a remarkable outcome. Many buildings previously used electric resistance heating, which is less efficient than a typical air-source heat pump, and much less efficient than networked geothermal heat pumps. By switching to the GEN, this particular neighborhood will likely reduce the load on the electric grid.

BDC’s Ashley and Ania stand by the SCADA panel, which monitors the system’s processes. Unseen on the other side of the door is the intimidatingly-named “interrogator,” which receives measurements from the distributed fiber optic cables.

Eric Juma explains: “The data will be used to help optimize the performance of this system. HEET is making this data and our resulting research available for public use. As more utilities consider networked geothermal, this access to real-time, high-resolution thermal data will be valuable for refining future designs, improving efficiency, and optimizing system performance. Now that we have the numbers flowing in, I’m excited for our LeGUp research team to dig into it and see what we learn.”

We begin our walk through the neighborhood, following the invisible, buried loop of the underground pipe.

Our first clue that the geothermal network is beneath us: A geothermal pipe cap. Beneath this, geothermal magic is happening (well, water is equalizing with the ambient temperature of the earth).

We set off to view the homes and businesses served by the geothermal network. It connects about 135 customers, including single-family homes, Framingham Housing Authority apartment buildings, a gas station, two schools, and the Framingham Fire Department.

On the side of this school, you can see portions of geothermal pipe on the exterior of the building to a rooftop-mounted heat pump; the vast majority of the pipe is underground.

Framingham Fire Department is another customer of the geothermal loop.

These Framingham Housing Authority buildings have a storied history. They were originally World War I barracks, then veteran housing, and are now one-bedroom apartments that remain home to a large number of veterans and elderly residents.

So far, about half of these apartments have joined the geothermal network. Eversource is expanding the network, and the rest of the apartments will soon join.

Even a gas station is a customer!

At the end of the tour, we gather by the pump house and circle the manhole-covered portal to the borefield. (Saying “geothermal network” at once didn’t quite work, so we just smiled for the camera.)

For an invisible system, there was quite a lot to see: the groundwork, both literal and figurative, of a future where thermal energy networks and geothermal technologies quietly, invisibly, serve neighborhoods across the country.